Deep Spinning

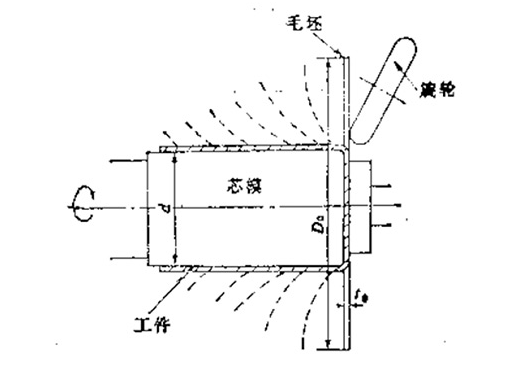

As shown in the figure, a round plate is installed on the core mold to rotate the main shaft, and the spinning wheel is pushed to move along the core mold and form. During the processing, the spinning wheel is reciprocated several times along the dotted line track shown in the figure, and the final shape is gradually formed. This processing method is called multi pass deep drawing and spinning.

This spinning method is the most commonly used spinning processing method. It can make a variety of shapes and control the wall thickness of products after spinning when the material ductility allows. However, the preparation of its trajectory is very complex, which requires a high level of process personnel.